The MIL-DTL -5015 AIT/MS series is a cost-effective threaded circular connector for use in harsh environments. These Amphenol connectors are sealed to withstand moisture, condensation, vibration and flash-over. Over 286 contact layouts are available, in variations that allow for just power, just signal, or a mix of both contact types. Available in five mounting styles, nineteen shell sizes, and solder or crimp termination.

Application:

Military, industrial and commercial environments requiring extreme reliability, high-power handling and cost efficiency. Widely used in Power generators, Off-road vehicles, Industrial machinery, Engines, Earth-moving equipment, Telecommunications, Sensors, Ships, Motion Control, Mobile equipment

Feature:

Agency Approvals

MIL -DTL -5015 (Formerly MIL -C-5015)

Broad Temperature Range

These connectors will operate in temperatures ranging from -67°F to +257°F (-55°C to +125°C).

Environmental

These connectors will perform in the full range of operating conditions as defined in MIL-DTL-5015 and are recommended for conditions where vibration, moisture, pressure and/or temperature are extreme.

Resilient Insul and Grommet

A resilient neoprene insulator and rear-seal grommet provide a liquid-tight assembly.

Rugged Shell

The rugged aluminum alloy shell and hardware are light in weight yet highly resistant to damage and corrosion. Shells are available in five different styles and in 19 sizes.

Wide Range of Wire Gauges and Current Carrying Capacity

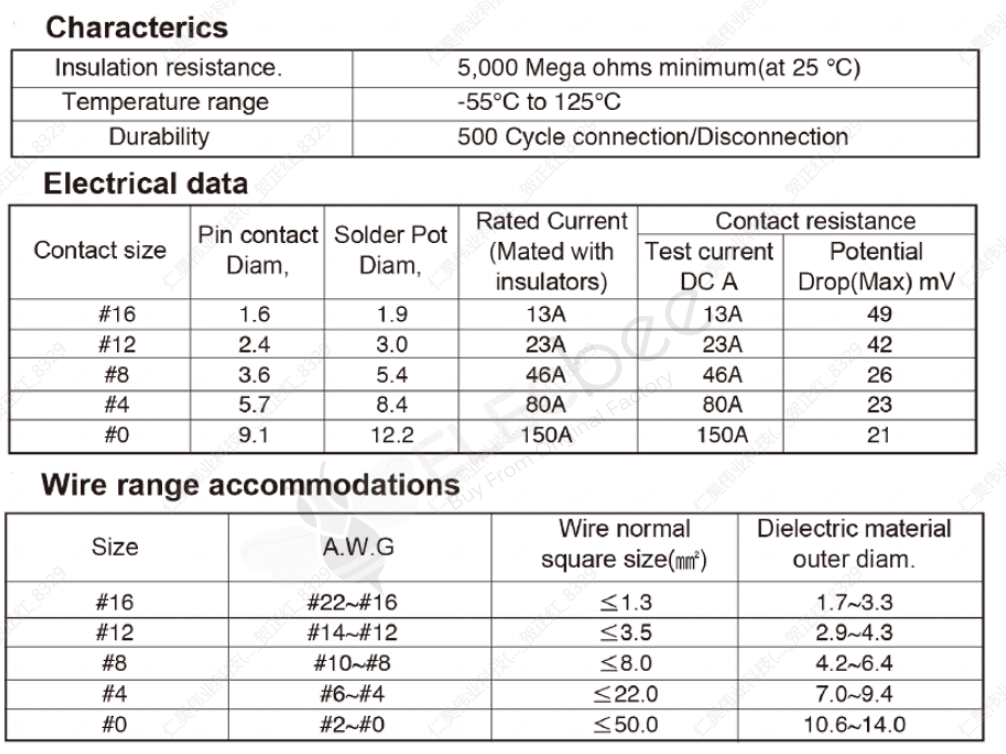

Up to 150 amps for standard military contacts, wire gauges from 24 to size 0 AWG.

Wide variety of Contacts

Machined contacts with silver or gold plating are available in sizes from 16 through 0. Solder, Crimp, PC, and thermocouple contacts are available.

Technical specification:

Materials & Finishes

Shell: Aluminum alloy

Plating: Olive drab chromate coating over cadmium plating to QQ-P-41 6; black alloy,

electroless nickel, anodized, gray zinc nickel or green zinc

Contacts: Brass or copper alloy

Contacts Plating: Silver plating to ASTM B700 (solder contacts have tinned solder pot) gold plating to ASTM B488

Mechanical Characteristics

Mechanical:

Mating Life: 100 cycles minimum

Salt Spray: MIL-STD- 1344 Method 1001 condition B minimum (cadmium),

48-hour olive drab chromate over cadmium, non-conductive black alloy,

conductive black alloy, green zinc, black anodized, electroless nickel, Gray Zinc Nickel 500 hours salt spray.

Heat: +257°F (+125°C) for 60 hours, +185°F (+85°C) for 1 ,000 hours per MIL -DTL-5015, 4.6.14, minimum

Chemical Resistance: 20-hour full-immersion unmated in hydraulic fluid and lubricating oil per MIL-DTL -5015 minimum

Vibration: 10 to 2000Hz (10g's) 10 microseconds maximum discontinuity to MIL -STD-1 344 Method 2005, condition II per MIL-DTL-5015

Shock: 50g 11 millisecond duration, three major axes.

10 microseconds maximum discontinuity to MIL-DTL-5015

per MIL -STD-1344 method 2004, condition A, 3.13

Contact Type: Solder, crimp, PC, or thermocouple (hard silver or gold plating).

Contact Insertion: Insertion from rear with simple hand tool. Removable, five cycles minimum

Elecbee offers a complete line of MIL-DTL-5015/MIL-C-5015 type solder connectors. Elecbee Series connectors are built to meet and exceed all performance specifications for the military MIL-DTL-5015 standard. In addition, the series provides a complete offering of accessories to ensure complete protection and reliability. These heavy duty, environmentally resistant connectors offer the protection required for signal and power applications in harsh environments. The Elecbee Series provides a versatile and high-performance, yet economical, solder terminated metal connector solution designed for mission success.

For additional help in specifying your 5015 connector solution, please contact contact us freely