Definición de conector

Un término general para conectar dos o más dispositivos de circuito. Como componente electromecánico, los conectores generalmente funcionan en pares y se dividen en enchufes (macho) y enchufes (hembra).Completa la conexión y desconexión de aparatos eléctricos mediante determinadas acciones mecánicas. Sus principales funciones son:

Transmitir señales o transmitir energía eléctrica

Hacer o romper un circuito

Clasificación de conectores

Hay muchas formas de clasificar los conectores, en las que nos centraremos en este artículo. Sin embargo, debido a las diferentes direcciones de aplicación de los conectores, existen tipos de contacto y sin contacto. Por ejemplo, los conectores de fibra óptica y los conectores eléctricos son del tipo de contacto, y los interruptores de proximidad son conectores sin contacto. ; También hay clasificaciones de señales eléctricas y ópticas. Hoy hablamos principalmente de conectores de contacto para señales eléctricas.Los conectores electrónicos y sus componentes son importantes componentes de interfaz de soporte en el equipo, dispersos en varios sistemas y partes del equipo, responsables de la transmisión de señales y energía. La calidad de la conexión está directamente relacionada con el funcionamiento seguro y fiable de todo el sistema.

Varios circuitos están interconectados por conectores eléctricos, de alta frecuencia a baja frecuencia, de circular a rectangular, de conectores de alta corriente que pasan cientos de amperios a conectores de alta densidad que pasan señales débiles, de conectores de placa impresa ordinarios Casi todos los tipos de conectores eléctricos tienen ha sido ampliamente utilizado en varios sistemas de ingeniería, desde conectores especiales como la separación y el desprendimiento rápidos, para garantizar el desempeño normal de las funciones completas del equipo.En resumen, por un lado, ante varios tipos de escenarios de aplicación, la clasificación de los conectores industriales es extremadamente complicada. Por lo tanto, con el avance continuo de la tecnología, cada vez se utilizan más conectores en el mercado y el rendimiento de los diferentes tipos de conectores también es muy diferente. Los fabricantes utilizarán materiales con diferentes características para diseñar conectores de acuerdo con el entorno de aplicación. Asegure el uso estable y confiable del conector en diferentes entornos.

Por otro lado, la confiabilidad de la conexión eléctrica determina directamente el desempeño del sistema del equipo. El rendimiento de los conectores electrónicos es una evaluación general del rendimiento. A diferencia de los terminales del conector, el rendimiento se puede evaluar fácilmente desde los aspectos del material, el diseño y el proceso.

Aunque hoy en día hay muchos tipos de conectores, y la selección es un poco problemática para la evaluación del rendimiento, los beneficios de usar conectores en equipos son obvios:

1. Mejorar el proceso de producción, el conector simplifica el proceso de ensamblaje de productos electrónicos y también simplifica el proceso de producción en masa;

2. Fácil de mantener y actualizar;

3. Mejorar la flexibilidad del diseño. El uso de conectores permite a los ingenieros tener una mayor flexibilidad al diseñar e integrar nuevos productos y al componer sistemas con componentes. La cantidad de cables en el extremo del conector y el espaciado de los cables hacen que la conexión sea más conveniente y rápida. Son estos pequeños detalles los que pueden reducir efectivamente el volumen de productos electrónicos y, al mismo tiempo, reducir los costos de producción. Puede usarse efectivamente como una línea de datos para la transmisión entre placas principales móviles o entre PCB.

Hay tantos conectores, ¿cómo dividirlos?

Para cualquier producto moldeado, los conectores son esenciales, como nuestro USB de uso común, el conector para auriculares, la interfaz Ethernet o nuestra interfaz militar personalizada menos común. Por lo tanto, en base a una amplia gama de mercados, las clasificaciones de conectores también son diversas.

1. Según las funciones de las conexiones internas y externas de los equipos electrónicos, los niveles de interconexión se dividen en 6 tipos:

A: Interconexión de componentes a paquetes;

B: La interconexión del paquete a la placa de circuito;

C: interconexión placa a placa;

D: interconexión de componente a componente;

E: Interconexión de componentes a interfaces de entrada y salida;

F: Interconexión de sistema a sistema.

2. Clasificación según el tipo de señal de transmisión:

A: conector de alimentación (potencia de transmisión);

B: conector de señal (señal de transmisión);

C: Conector de alta frecuencia (transmisión de datos).

3. Clasificación según requisitos eléctricos:

R: conector universal;

B: conector de alta potencia;

C: conector de alto voltaje;

D: conector de pulsos;

E: conector de bajo ruido;

F: conector de modulación de fase;

G: Conector coaxial de precisión.

4. Clasificación según la frecuencia de trabajo:

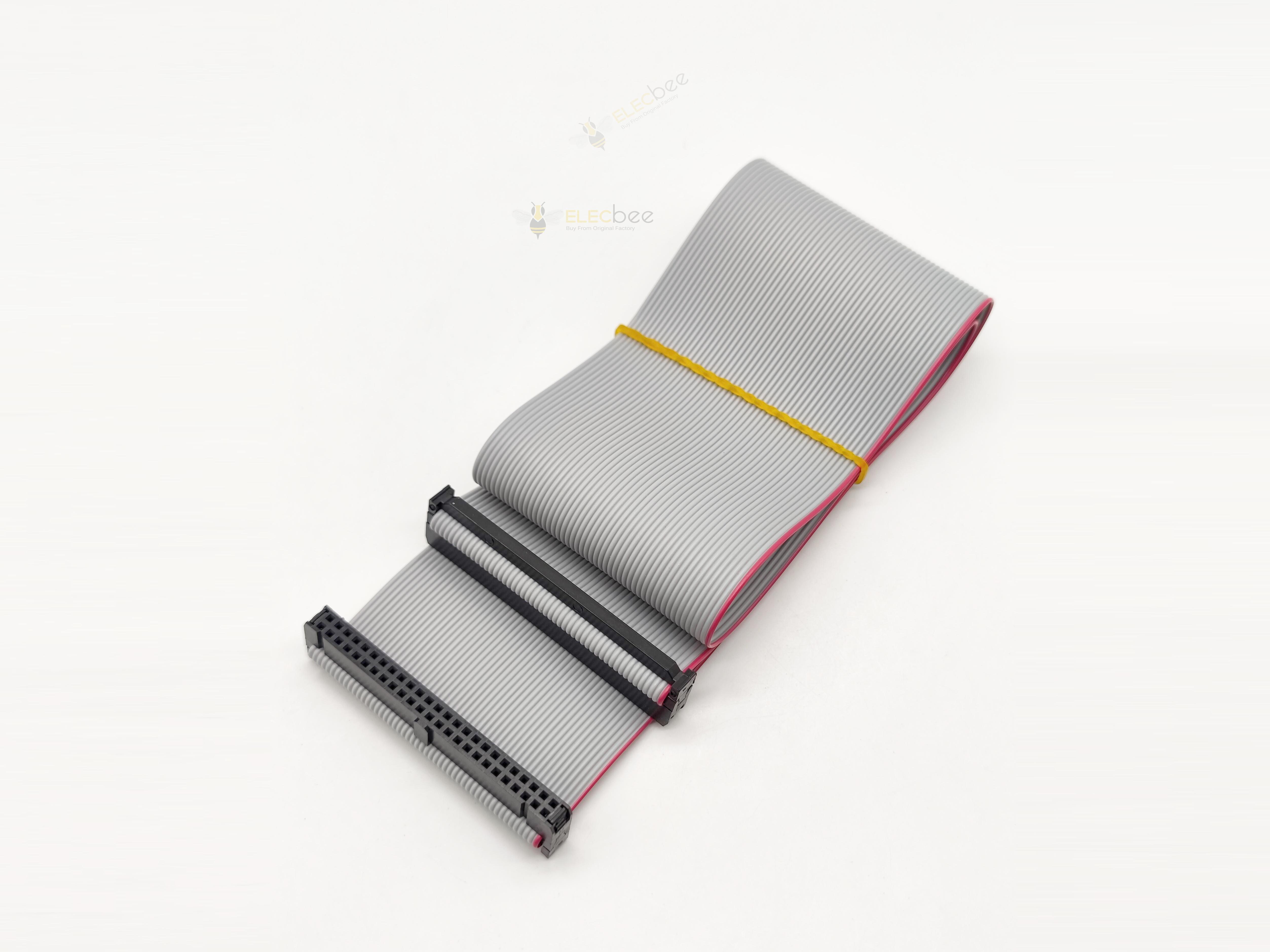

Conectores de alta frecuencia, conectores coaxiales de alta frecuencia, conectores de video, convertidores coaxiales, convertidores de impedancia, convertidores de tamaño de acoplamiento, convertidores de género, convertidores coaxiales Microstrip, convertidores coaxiales de guía de ondas, conectores de carga coincidente, conectores de baja frecuencia, conectores de placa impresa, conectores de cable plano , conectores de circuito integrado, conectores mixtos, etc.

5. Clasificación según condiciones ambientales:

A: conector sellado;

B: Conector del sello de alta presión de agua;

C: conector sellado de alto vacío;

D: conector de tres pruebas;

E: conector resistente a la radiación;

F: conector de alta temperatura;

G: Conector criogénico.

6. Clasificación según la forma:

Conectores circulares, mayoritariamente utilizados en equipos militares; (Las formas de conexión incluyen principalmente bayoneta (rápida), rosca, bloqueo automático, push-pull, enchufe recto, etc.)

Los conectores rectangulares se utilizan ampliamente y se desarrollan rápidamente. Muchos conectores a nivel de placa son conectores rectangulares. (Por lo general, existen dos tipos de métodos de conexión para enchufes y tomas: enchufe recto y enchufe recto y bloqueo de tornillo).

7. Clasificación según la dirección de aplicación:

R: conector RF;

B: conector de fibra óptica;

C: Conector sin contacto (como interruptor de proximidad, etc.)

Todas las clasificaciones anteriores se basan en atributos externos o de aplicación, y cada fabricante es diferente. Aunque NEDA ha formulado un estándar de clasificación para el empaquetado de componentes de conectores, con el avance de la tecnología, la clasificación de conectores se ha vuelto más complicada. Sin embargo, en términos de conectores de comunicación, debido a la cooperación de los protocolos de software, hay pocos y se pueden distinguir de manera efectiva.

A. Conectores de cable multifilar, incluidos conectores DB, conectores DIX y conectores DIN.

B. Conectores de par trenzado, incluidos los conectores RJ45 y RJ11;

C. Los conectores de cable coaxial incluyen conectores T, conectores BNC y resistencias terminales.

Elecbee es una empresa especializada en la investigación y desarrollo, producción y venta de conectores electrónicos, adaptadores y antenas. Ya sea tecnología, investigación y desarrollo, producción o negocios, se encuentra en la posición de liderazgo en la industria. Si desea saber más sobre nuestros productos o necesita ayuda y soporte relacionados, puede comunicarse directamente con nuestro personal técnico en tiempo real en el sitio web o enviar un correo electrónico a service@elecbee.com. Todo el personal de Elecbee espera cooperar con usted.