고전압 시스템이 작동 중일 때 전류는 수십 암페어 또는 수백 암페어로 높습니다. 기존의 저전압 커넥터에 비해 고전압 커넥터는 더 높은 전압과 전류를 견뎌야 합니다. 자동차 진동, 범프, 비, 눈, 모래 등 가혹한 환경에 직면하면 고압 연결 시스템의 고장 확률도 크게 증가하며 한번 문제가 발생하면 과열로 차량의 기능에 영향을 미치거나 연소 사고를 일으켜 사용자의 안전을 위협하게 됩니다. 따라서 신에너지 자동차는 고전압 커넥터의 안전성과 신뢰성에 대해 더 높은 요구 사항을 제시합니다.

고전압 커넥터의 품질을 보장하기 위해 제조업체는 오프라인 상태에서 전기적 성능, 기계적 성능, 기밀성 및 환경 적응성에 대한 포괄적인 테스트를 수행하지만 이는 고전압 커넥터가 안전하고 안전하다는 것을 보장하지 않습니다. 나중에 사용하는 과정에서 신뢰할 수 있습니다. 현장 사용 및 실험 데이터에 따르면 자동차 고전압 커넥터의 다양한 고장 모드 중에서 전기 접촉 고장이 가장 큰 비율인 약 45%를 차지합니다. 다양한 실패 모드와 그 비율이 아래 그림에 나와 있습니다. 주요 제조업체는 일반적인 고전압 인터록 기능과 같은 고전압 커넥터 고장 설계를 방지하기 위해 많은 작업을 수행했지만 터미널 시장에는 여전히 많은 고전압 커넥터 고장 문제가 있습니다.

01 전기적 접촉불량

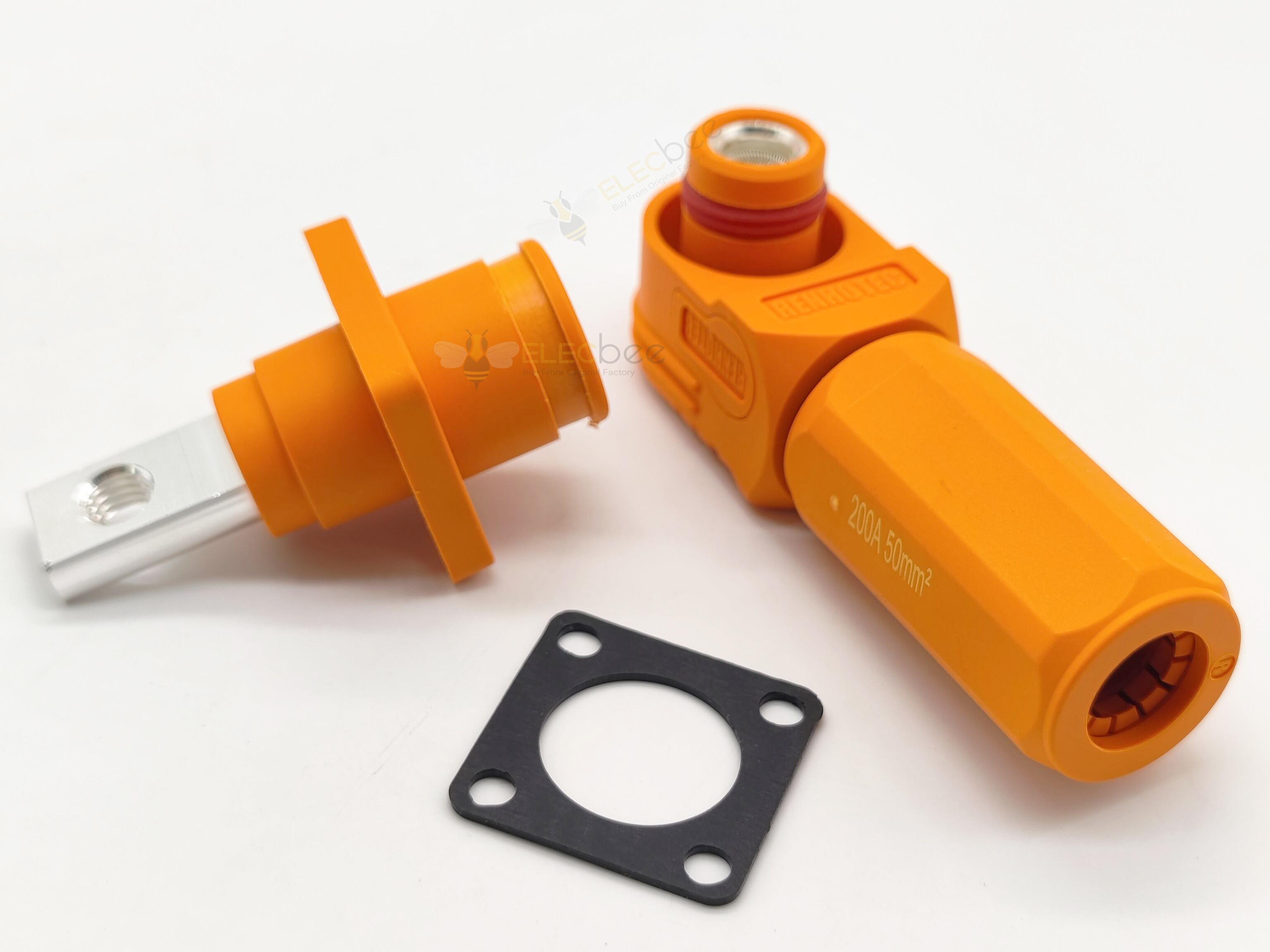

전기 접점 불량의 원인은 일반적으로 전기 접점 압력 부족, 접점 마모 등이 있습니다. 신에너지 자동차용 고전압 커넥터의 구조는 아래 그림과 같으며 주로 접점, 차폐층, 하우징 및 액세서리로 구성됩니다. . 그 중 접촉부는 전기 에너지 전달을 담당하는데, 이는 전기적 접촉 불량을 일으키는 주요 취약 고리입니다. 차량 진동, 편심 삽입, 금속 변형, 이물질 간섭 등으로 인해 고압 커넥터의 접촉 부분이 접촉 불량 및 접촉 저항이 증가합니다. 큰 전류가 흐르면 열이 심합니다.

02 절연불량

표면 수막과 융합하여 이온 전도성 채널을 형성하는 고전압 커넥터의 표면에 수분 및 부식성 물질이 있을 수 있습니다. 이러한 결과가 나온 이유는 단열재 표면의 일부는 청소가 어려워 품질 검사 과정에서 엄격하게 선별해야 하기 때문입니다. 절연 저항을 테스트하기 위한 전압은 DC이고 절연 내력 테스트를 위한 전압은 AC입니다. 절연 저항을 테스트하기 위한 전력은 절연 내력을 테스트하기 위한 전력보다 훨씬 낮습니다.

03기계적 연결 불량

전기 커넥터의 기계적 연결 실패는 프로세스 및 사용 프로세스와 분리할 수 없는 다양한 실패 모드로 나타납니다. 용접, 압착, 설치 및 응력 상태는 기계적 연결의 약한 연결 고리입니다. 기계적 연결 실패는 일반적으로 사용 중에 문제를 노출시킵니다. 상대적으로 요구 사항이 높은 제품의 경우 조기 선별 및 평가 테스트를 수행하여 사용 신뢰성을 향상시킬 수 있습니다.

실제로 과학 기술의 발전으로 사람들은 고전압 커넥터의 점점 더 많은 고장 문제를 해결해야 하며 고전압 커넥터의 고장 모드는 이보다 훨씬 많습니다. 그리고 더 많은. 조기 스크리닝 및 평가 테스트는 실제 생산 작업에서 수행할 수 있습니다. 고전압 커넥터는 신에너지 차량의 고전압 구성 요소 사이의 연결 고리이며 그 신뢰성은 차량의 기능과 안전에 직접적인 영향을 미칩니다.

Elecbee는 전자 커넥터, 어댑터 및 안테나의 연구 개발, 생산 및 판매를 전문으로 하는 회사입니다. 기술, 연구 개발, 생산 또는 비즈니스에 관계없이 업계 최고의 위치에 있습니다. 당사 제품에 대해 더 알고 싶거나 관련 도움 및 지원이 필요한 경우 웹 사이트에서 당사 기술 직원과 실시간으로 직접 통신하거나 service@elecbee.com으로 이메일을 보낼 수 있습니다. 모든 Elecbee 직원은 귀하와 협력하기를 기대합니다.