In the field of new energy vehicles, the new energy vehicle connector is an important device, which is mainly composed of contacts, insulators, housings and accessories. Since the working voltage range of new energy vehicles is increased from 12V of traditional vehicles to 400V, the connection The quality and accuracy of the device put forward higher requirements, and it is used in the whole vehicle and charging facilities.

The new energy vehicle connector on the vehicle is used to connect the following systems: power battery, high-voltage wiring harness, switch, electric air conditioner, DCDC, charger, DC charging port, AC charging port, motor, inverter, etc. Thermal and current-carrying capacity are the key factors to be considered during development.

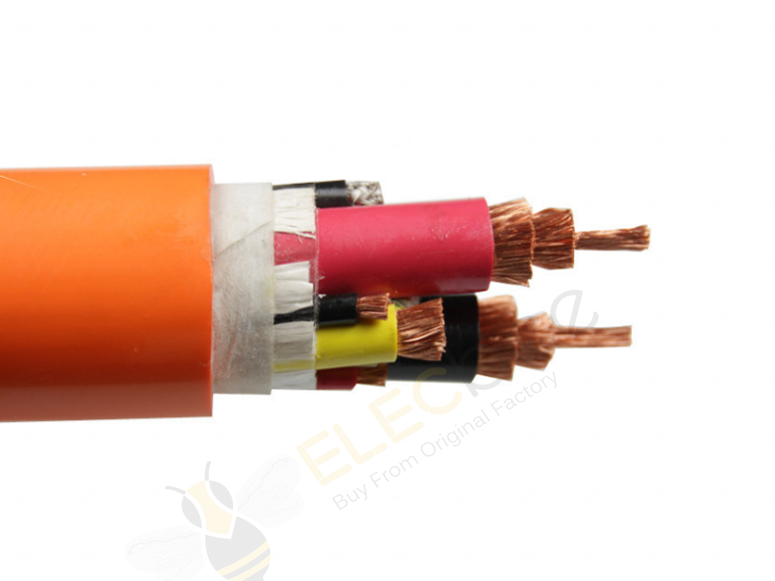

High voltage and high current are the power type. They are used from the charging port to the battery, from the battery to the motor. There are also inside the battery pack. In addition to the power, there are also signal control, instrumentation, temperature, and lighting. , control, etc., the others are various sensors, BMS, entertainment systems, etc.

In terms of material selection, new energy vehicle connectors should use materials with high temperature resistance, and their requirements for sealing, shielding and waterproofing are also higher than those of traditional automotive connectors, so the cost is also higher. From the perspective of technical composition, electronic control, There are many patents for motor connectors, and fewer improvements to charging, battery connectors, and grounding shielding.

Pure electric vehicles and plug-in hybrid electric vehicles have operating voltages over 300V, operating currents are usually several hundred amps, and high-voltage cables are electric. The reliability and safety of vehicle operation are guaranteed. Different from the 12V voltage of traditional vehicles, high-voltage cables need to consider preventing overheating or burning, shielding performance, waterproof and dustproof, and electromagnetic compatibility with the electrical system of the vehicle.

In actual use, the magnetic interference generated by high-voltage cables will affect the integrity and accuracy of data transmission in automobile signal lines, and in severe cases, it will affect the safety of the entire vehicle. Therefore, high-voltage cables need to be shielded. To reduce magnetic interference, cables involving battery pack voltage acquisition and temperature acquisition have high requirements on the crimping process, and hydraulic equipment needs to be used to replace the traditional process. In order to reduce fuel consumption, aluminum is used to replace the currently widely used copper for processing. High-voltage cables are also a trend of technological development.

Elecbee is a company specializing in the research and development, production and sales of electronic connectors, adapters and antennas. Whether it is technology, research and development, production or business, it is in the leading position in the industry. If you want to know more about our products or need related help and support, you can directly communicate with our technical staff in real time on the website or send an email to service@elecbee.com. All Elecbee staff look forward to cooperating with you.