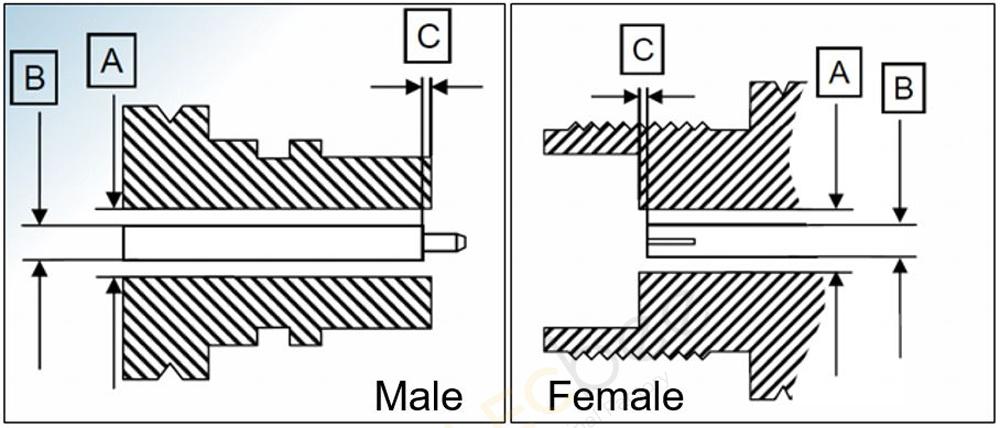

1. Dimensions of SMA and extension series connectors:

The inner diameter of the outer conductor (this parameter and the diameter of the center conductor and the dielectric constant of the insulating layer determine the maximum cut-off operating frequency of this joint; many joint names are derived from this diameter index, such as 3.5mm, 2.92mm, 1.85mm, etc.)

The outer diameter of the center conductor (combined with the inner diameter of the outer conductor, the impedance of the joint can be determined)

Clearance of the center conductor: It is very important to confirm that the clearance of the center conductor is within the specification range, otherwise it may cause mechanical damage to the connector of the device or device.

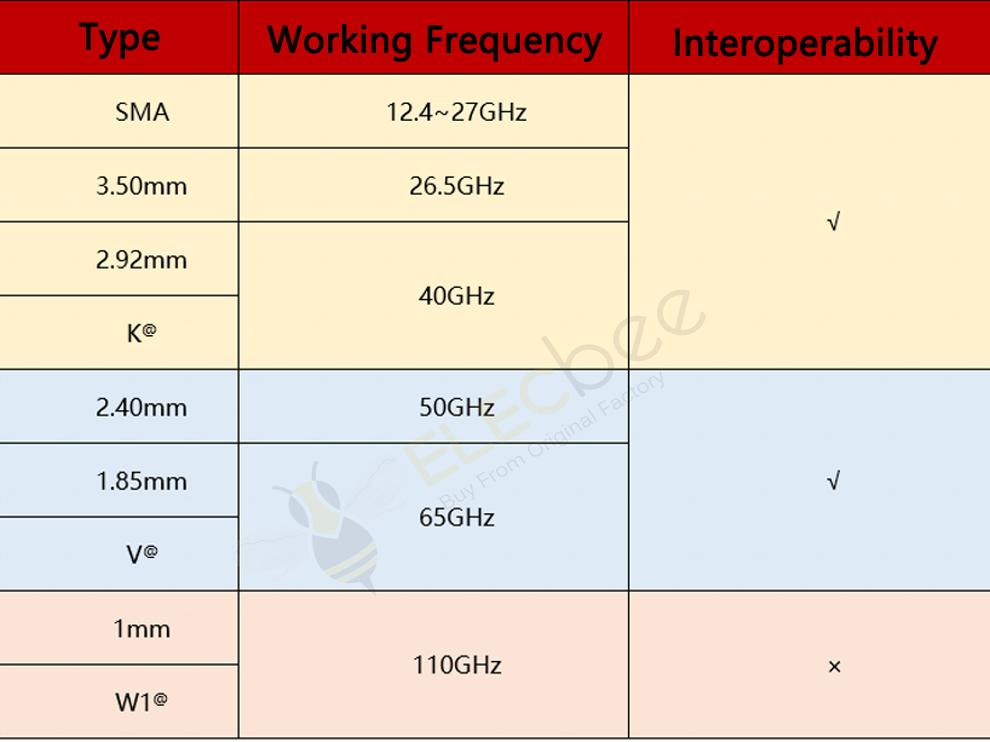

2. Interoperability specification for SMA series connectors

The interconnection of different types of connectors is related to the size of the connector. The specific size of each type is not described in detail here. The maximum operating frequency and interoperability of different types of connectors are given below:

3. Introduction of adapters that communicate with different connectors

If you want to realize the intercommunication between the connectors that cannot communicate with each other, you can use the adapter to transfer and communicate with each other; for example, the 2.9mm female connector cannot be matched with the 2.4mm male connector, then one end can be 2.9mm male, and the other One end is a 2.4mm female connector for transfer.

Even between the same type of connectors, male-to-male, female-to-female, etc. can be transferred; for example, if a 2.9mm female connector is to be connected with a 2.9mm female connector, it can be connected by a 2.9mm connector on both ends. One connector of the male head is used for transfer.

Precautions for the use of connectors

Since the connector is also a precision instrument, it is also very important to inspect and clean the connector regularly. The inspection and cleaning steps are as follows:

1. Use a microscope with 20X magnification to inspect the microwave connector;

2. If cleaning is required, please ensure that all equipment and operators are grounded;

3. Please avoid using connectors with mechanical damage (the connection surface is scratched, the center conductor is abnormal or bent);

4. Please use cotton swabs and anhydrous alcohol for cleaning. Excessive force or alcohol injected into the insulator will cause damage when cleaning the center conductor;

5. All alcohol and dust particles must be blown clean with compressed air and sprayed vertically to prevent residues from remaining on the joint.

Elecbee is a company specializing in the research and development, production and sales of electronic connectors, adapters and antennas. Whether it is technology, research and development, production or business, it is in the leading position in the industry. If you want to know more about our products or need related help and support, you can directly communicate with our technical staff in real time on the website or send an email to service@elecbee.com. All Elecbee staff look forward to cooperating with you.