What is M8 Series connector?

The M8 connector is used specifically with industrial sensors and features a waterproof 3-pin screw. These connectors come pre-assembled and remain watertight even if submerged. These heavy-duty connectors are typically used in harsh environments. A major advantage of using the M8 connector, as well as the M12 connector, is the time saved in installing wiring systems and maintaining it. This reduces setup time and the need for electricians or technicians.

What is M12 Series connector?

The M12 connector is a circular connector with a 12-mm locking thread that is used primarily in factory automation applications for actuators, sensors, industrial ethernet, and Fieldbus. M12 connectors are designed for wash-down and corrosive environments.

Applications for M8 and M12 interconnect systems

M8 and M12 have become favorites for anyone in need of a rugged, sealed connector. In addition to automotive production, other industries that call for specific cables to best meet reliability demands include food and beverage processing environments, machine building, rubber and plastics, textile and printing presses. They’re also seen connected to spray valves on farm implements or coolant valves in HVAC systems. The wide variety of cable types, connector orientations and keying options allows M8 and M12 connectors to address a range of situations and applications.

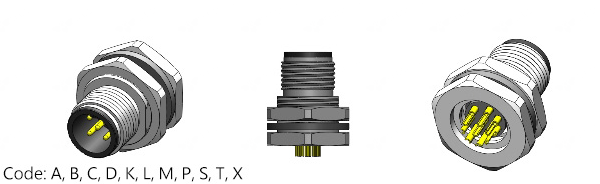

Since the introduction of the 3- and 4-pin versions of the M12, many more variations and options have become available. The connectors are offered in both straight and right angle configurations and can now be found in 3-, 4-, 5-, 6-, 8- and 12-pin versions. In addition to IP67, M12 connectors are offered with IP65, IP68 and IP69K ratings. This allows the M12 to be used in the most demanding applications, even where high-pressure washdown processes are required. IP69K applications often require resistance to corrosion, which can be achieved by using stainless-steel coupling nuts. The M12 is also available in the following keying/coding options:

• A-code—primarily used with sensors and actuators

• B-code—PROFIBUS fieldbus connections

• C-code (dual keyway)—primarily used with ac sensors and actuators

• D-code—100 MB Ethernet/IP 4-pin

• X-code—Gigabit Ethernet 8-pin

This covers the options for the connector itself, but the number of options grows substantially when you consider all of the different cable types that are available.