Un elemento muy importante en la electrónica automotriz son los conectores FAKRA y HSD. Estos productos son ampliamente adecuados para el campo de Internet de los vehículos y pueden elevar el nivel de seguridad y confiabilidad de los sistemas de entretenimiento multimedia en vehículos y los sistemas electrónicos automotrices a un nuevo nivel. Es de gran importancia para todo el sistema de Internet de los vehículos relacionado con la seguridad del sistema del vehículo. Ha sido ampliamente utilizado en la actualidad.

El llamado FAKRA es un conector de audio y antena para automóviles lanzado conjuntamente por 12 fabricantes de automóviles europeos y estadounidenses liderados por fabricantes de automóviles alemanes en 2000, con un máximo de 40 pines. General FAKRA debe cumplir con los estándares automotrices USCAR estadounidense y FAKRA alemán. FAKRA tiene las características de alto rendimiento, características de RF rentables, etc.

FAKRA es la abreviatura de FAchKReis Automobil (el equipo de expertos en automoción está compuesto por ingenieros de BMW, Huber-Suhner, Rosenberger y otras empresas, y el negocio y la tecnología de conectores relacionados de Huber-Suhner se fusionó con Rosenberger en 2010). Utilizado originalmente por BMW para la conexión de antenas de radio de automóviles, FAKRA se ha convertido en un conector de RF estándar común en la industria automotriz y es ampliamente utilizado en la industria.

La primera generación de productos FAKRA lanzados por Rosenberg en 2000 se basó en la interfaz SMB del conector RF y agregó una estructura de caja de plástico. La integración de la caja de plástico hizo que el producto FAKRA fuera adecuado para un montaje rápido en el vehículo y aseguró que la conexión fuera estable y no se desconectara.

El producto FAKRA de segunda generación optimizó el diseño, aclaró los requisitos de rendimiento estándar de la interfaz y escribió los requisitos en ISO20860-1 lanzado en 2004. Los productos de segunda generación se completan principalmente girando.

Rosenberg lanzó FAKRA de tercera generación en 2007, optimizando el costo y manteniendo el rendimiento de la segunda generación. Los productos de tercera generación se procesan principalmente mediante estampado (el procesamiento por estirado también se utiliza en la industria), que es más adecuado para la producción completamente automatizada.

2. Introducción básica

2.1 Parámetros de rendimiento del conector FAKRA

De acuerdo con los requisitos de parámetros en IS0 20860.

Principales parámetros de rendimiento eléctrico: frecuencia de transmisión 0-4GHz; impedancia característica 50 ohmios; corriente de transporte máxima 1A

Principales parámetros de rendimiento mecánico: fuerza de retención de bloqueo≥Fuerza a prueba de errores 100N≥40N

2.2 Aplicaciones comunes

Transmisión de señal inalámbrica: vehículo AM/FM; GPS; redes de automóviles (2 ~ 4 GHz, incluida la transmisión); control remoto, etc

Aplicación de transmisión de señal de video: Basado en el brote de ADAS, se usa principalmente en cámaras.

2.3 Estándares relevantes

Estándar de diseño: ISO20860; USCAR18

Estándar de verificación: LV214; USCAR2; USCAR17

2.4 Cable adaptador

Modelos de cable de uso común: RG 174; RTK 031; RG59; RG179; RG58

2.5 rendimiento a prueba de agua

Usando la versión a prueba de agua del conector del extremo del arnés, se puede lograr el nivel de impermeabilidad de IPX7/IPX9K en la interfaz de acoplamiento del conector.

3. La estructura del conector Fakra.

3.1 La estructura general deelconectores del extremo del arnés

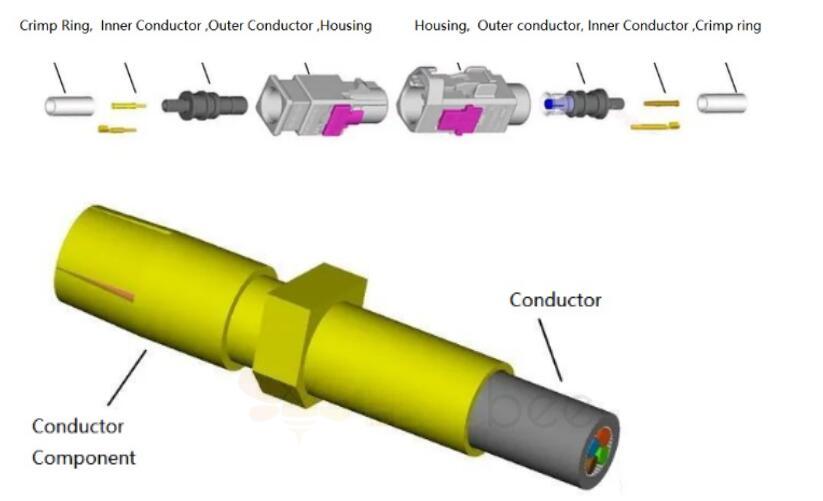

Un conector FAKRA común consta de una caja moldeada, un conductor exterior, un conductor central, un aislante, un manguito de engarce (solo el conector del extremo del arnés) y un bloqueo secundario (solo el conector del extremo del arnés).

3.2 Cerradura secundaria, color + prueba de errores mecánicos

Bloqueo secundario: asegura que la terminal esté en su lugar y aumenta la retención de la terminal. Las cerraduras secundarias suelen ser de color púrpura.

Color + prueba de errores mecánicos: hay un diseño estructural para evitar un acoplamiento incorrecto en la interfaz de acoplamiento del conector, y diferentes estructuras de prueba de errores tienen carcasas de plástico correspondientes de diferentes colores. Los conectores FAKRA de Rosenberg proporcionan 14 tipos de codificación a prueba de errores.

Codificación A: DAB (Difusión de audio digital)/equipo de radio sin soporte fantasma. El color de la caja de plástico es negro.

Codificación B: Equipo DAB/Radio con soporte Phantom. El color de la caja de plástico es blanco.

Codificación C: Sistema de posicionamiento global (satélite) GPS. El color de la caja de plástico es azul.

Codificación D: Sistema global de telefonía móvil GSM para comunicaciones móviles. El color de la caja de plástico es morado uva.

Codificación E: TV 1, Codificación F: TV 2. Los colores de la caja de plástico son verde y marrón respectivamente.

Codificación G: control remoto/sistema de entrada sin llave, la caja de plástico es gris.

Codificación H: GPS, la caja de plástico es de color violeta.

Codificación I: Calefacción de estacionamiento controlada por radio, la caja de plástico es de color beige.

Codificación K: Dispositivos inalámbricos con frecuencia intermedia (FI). El color de la caja de plástico es amarillo curry.

Codificación L, M, N: indefinido. Los colores de la caja de plástico son: carmín, rosa naranja, rosa verde.

Codificación Z: propósito general. La caja de plástico es azul aguamarina.