High Voltage Inter-lock (HVIL) es también la abreviatura de Hazardous Voltage Interlock Loop

El enclavamiento de alto voltaje se refiere a un método de diseño seguro para monitorear la integridad de los circuitos de alto voltaje con señales de bajo voltaje. Mediante el uso de señales de bajo voltaje para verificar todos los componentes conectados al arnés de cableado de alto voltaje en el vehículo eléctrico, se detecta la integridad de la conexión eléctrica (continuidad) de cada circuito del sistema de alto voltaje.

Teóricamente, el circuito de monitoreo de bajo voltaje se conecta primero y luego se desconecta que el circuito de monitoreo de alto voltaje, y se mantiene el avance necesario. El formulario de implementación de enclavamiento de alto voltaje específico puede tener diferentes diseños para diferentes proyectos.

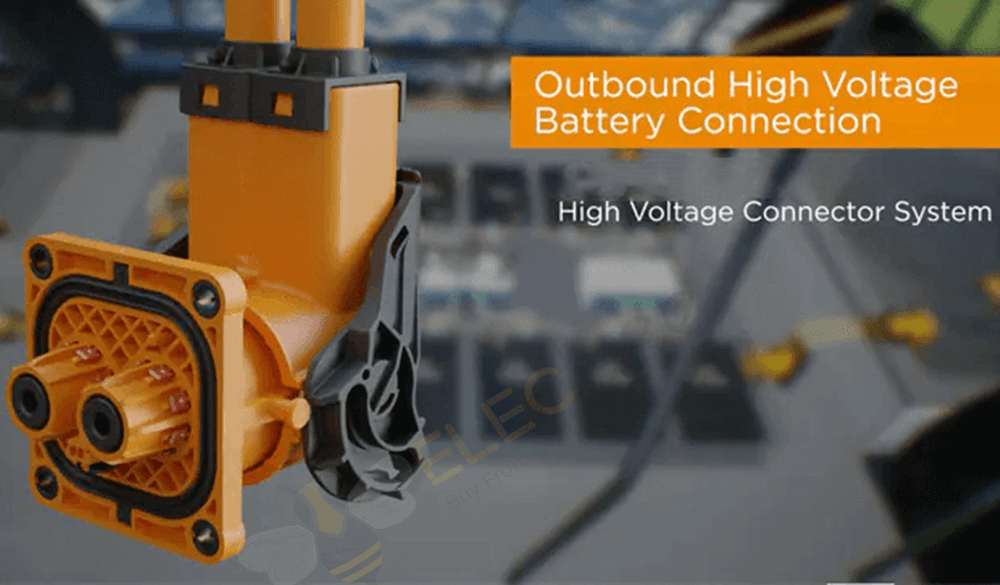

En el circuito de alta tensión de los vehículos eléctricos, los componentes eléctricos necesarios para tener la función HVIL son principalmente conectores de alta tensión, interruptores de mantenimiento manual (MSD) y otros componentes de interfaz eléctrica que requieren una operación manual para realizar la conexión o desconexión del circuito. .

1 Propósito del enclavamiento de alto voltaje

El propósito del enclavamiento de alto voltaje es confirmar la integridad de todo el sistema de alto voltaje. Cuando se desconecta el circuito del sistema de alto voltaje o se daña la integridad, es necesario activar las medidas de seguridad.

2 El papel del enclavamiento de alto voltaje, ¿por qué el diseño del enclavamiento de alto voltaje?

El enclavamiento de alto voltaje se utiliza principalmente para garantizar la seguridad del sistema de alto voltaje y tiene tres funciones principales:

En primer lugar, se utiliza para detectar la holgura del circuito de alto voltaje (lo que provocará un corte de energía de alto voltaje, el vehículo perderá energía y afectará la seguridad del automóvil), y para proporcionar información de alarma al controlador del vehículo. antes del corte de energía de alto voltaje, y reserve el sistema del vehículo para tomar contramedidas. tiempo.

La segunda es jugar un papel antes de encender el vehículo, y si se detecta que el circuito está incompleto, el sistema no puede encenderse para evitar accidentes causados por problemas como las conexiones virtuales;

El tercero es prevenir accidentes de seguridad causados por una mala operación humana. Durante el proceso de trabajo del sistema de alto voltaje, si no hay un diseño de enclavamiento de alto voltaje, desconecte manualmente el punto de conexión de alto voltaje. En el momento de la desconexión, todo el voltaje del circuito se aplica a ambos extremos del punto de interrupción y el aire de ruptura de voltaje dibuja un arco entre los dos dispositivos. , el tiempo es corto, pero la energía es alta, lo que puede causar daños al personal y al equipo alrededor del punto de ruptura.

Ahora creo que tienes una mejor comprensión deconectores de enclavamiento de alto voltaje. En la siguiente sección, los ingenieros de Elecbee explicarán el principio de funcionamiento y la implementación del enclavamiento de alto voltaje y el principio de funcionamiento de los conectores HVIL, o si desea obtener más información sobre el enclavamiento de alto voltaje, llame al + 86 18271418329 o envíe un correo electrónicoservice@elecbee.com, estamos de servicio en cualquier momento.