Choosing the right connector is crucial for ensuring stable signal transmission and equipment reliability. Among the most commonly used circular connectors, M12 and GX12 often confuse users due to their similar appearance but different specifications. This guide compares the two in detail and helps you select the right one for your project.

1.Overview of M12 and GX12 Connectors

Both M12 and GX12 connectors are circular connectors widely used in electronics and automation systems. However, they differ significantly in size, thread type, pin count, and application scenarios.

• M12 refers to a connector with a 12 mm locking thread designed for industrial automation.

• GX12 (also called an aviation plug) features a 12 mm circular shell with threaded coupling and is more common in DIY and light electronic devices.

2.M12 Connector: Structure, Features, and Applications

The M12 connector is designed for industrial automation, sensors, and Ethernet systems. It provides 3, 4, 5, 8, or 12 pins, supporting both signal and power transmission.

Key Features:

• IP67/IP68 waterproof protection for harsh environments

• Resistant to vibration and corrosion

• Screw-locking mechanism ensures secure connection

• Suitable for actuators, robotics, and fieldbus systems

Applications:

Robotics, Communication equipment, Measurement systems, Smart agriculture, Miniature sensors, Industrial camera, Electrical car, Packaging&Labeling & Logistic, Factory automation and fieldbus module

3.GX12 Connector: Design, Advantages, and Common Uses

The GX12 aviation connector is compact, affordable, and easy to solder, making it ideal for DIY electronics, LED systems, and low-voltage devices.

Main Features:

• Zinc-alloy shell and bakelite insulator for durability

• Silver-plated copper pins ensure excellent conductivity

• Rated for up to 250V, suitable for signal and low-power transmission

• Threaded coupling connection for stability

Typical Applications:

Audio equipment, LED lighting, RC models, Test instruments, Industrial Machinery, Space Flight and Aviation, Railway and Train, Petroleum Drilling, Cars and Heavy Trucks, Servo Motor

4.M12 vs GX12: Detailed Comparison Table

|

Feature |

M12 Connector |

GX12 Connector |

|

Outer Diameter |

12 mm (locking thread) |

12 mm (outer shell) |

|

Thread Type |

Metric thread (M12×1) |

Threaded aviation style |

|

Pin Count |

3–12 pins |

2–8 pins |

|

Voltage Rating |

Up to 400V |

Up to 250V |

|

Current Capacity |

10A |

5A |

|

Waterproof Level |

IP67/IP68 |

Non-waterproof |

|

Connection Method |

Crimp or solder |

Solder type |

|

Common Use |

Industrial automation |

DIY and consumer electronics |

5.How to Choose Between M12 and GX12 Connectors

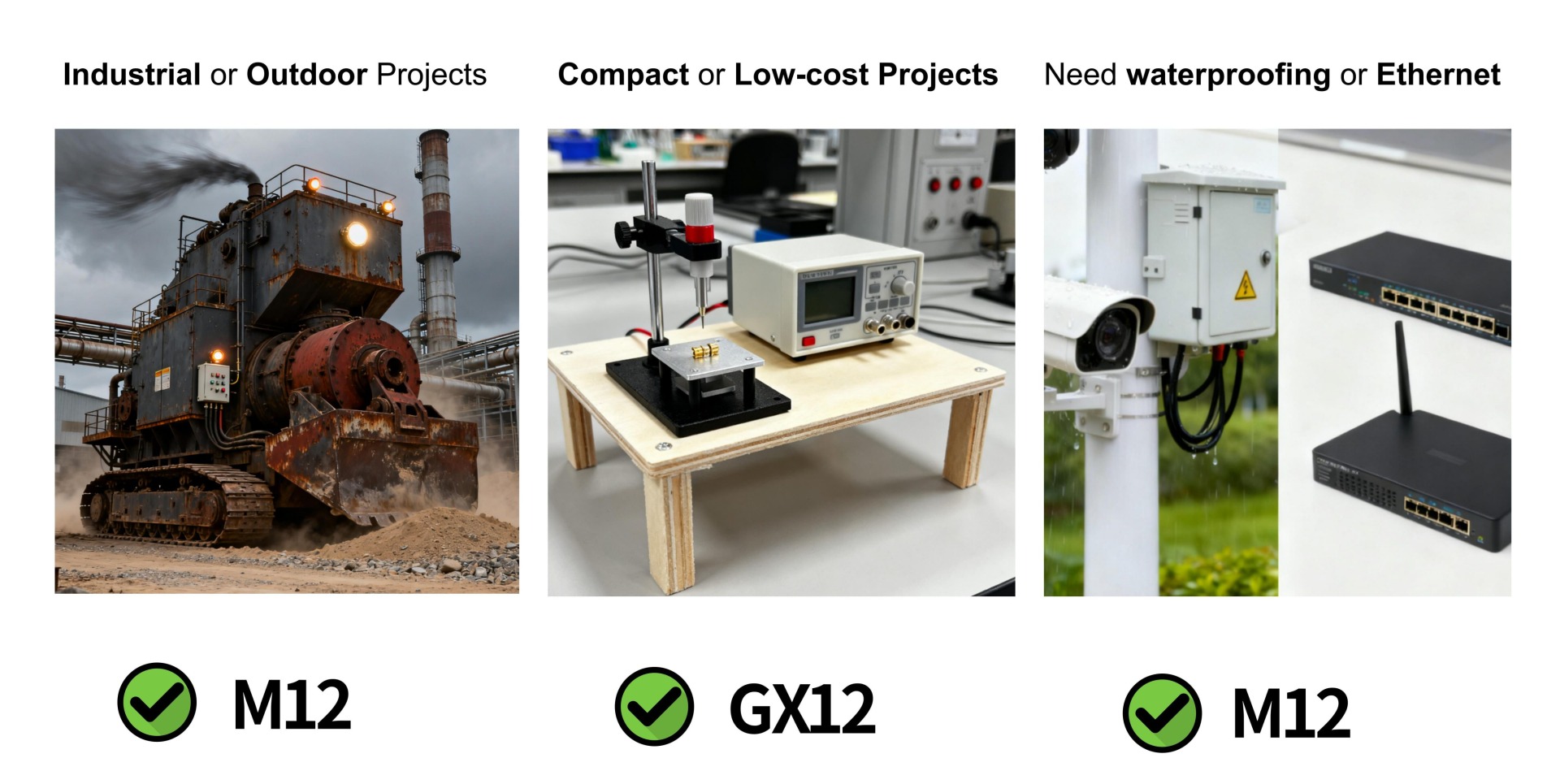

• For industrial or outdoor projects → Choose M12 connectors for better sealing, higher voltage, and vibration resistance.

• For compact or low-cost projects → Choose GX12 connectors, ideal for small devices and bench projects.

• Need waterproofing or Ethernet use? → Only M12 supports sealed designs and data communication protocols.

6.Frequently Asked Questions (FAQ)

Q1: Can M12 and GX12 connectors be interchanged?

No. They differ in thread type, pin layout, and dimensions.

Q2: Are GX12 connectors waterproof?

Standard GX12 connectors are not waterproof; choose M12 IP67 models for outdoor or wet environments.

Q3: What is the most common pin count for M12 connectors?

4-pin and 8-pin configurations are most common in sensor and Ethernet systems.

7.Conclusion

Both M12 and GX12 connectors have their unique advantages. M12 is the industrial-grade choice for demanding environments, while GX12 remains a cost-effective option for small projects.

For more details or to find compatible products, visit the M12 Series Connector or GX Series Connectors pages on Elecbee.