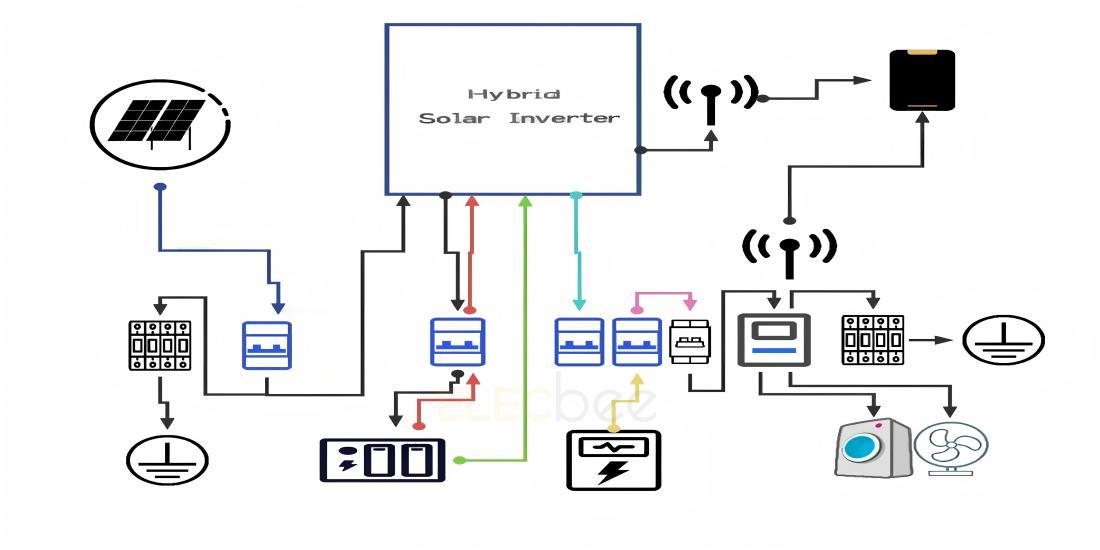

In modern solar energy systems, photovoltaic connectors are the small but crucial components that ensure the smooth transmission of power between solar panels, inverters, and junction boxes. Despite their compact size, these connectors determine the overall efficiency, safety, and durability of your solar setup.

1. What Is a Photovoltaic Connector and How It Works

A photovoltaic connector is an electrical coupling device used to connect solar panels within a photovoltaic (PV) system. It provides a secure, weatherproof, and low-resistance connection for DC power transmission.

Each connector typically consists of:

• Housing: Made from UV-resistant and flame-retardant plastic to withstand harsh outdoor environments.

• Contacts: Metal terminals (usually tinned copper or silver-plated) that ensure stable conductivity.

• Seals: Rubber or silicone O-rings that prevent dust and moisture ingress, guaranteeing long-term performance.

2. Main Types of Photovoltaic Connectors

2.1. MC4 Connectors (Most Common Type)

MC4 connectors are the global standard for solar installations. Designed for quick plug-and-play connections, they ensure secure locking and high current capacity. Most solar panels today come pre-installed with MC4 connectors.

Key Features:

• Voltage rating up to 1500V DC

• Waterproof (IP67) and flame retardant

• Compatible across major solar panel brands

2.2. Branch and T-Connectors

Branch connectors (Y-connectors) and T-connectors allow multiple solar panels to be connected in parallel, increasing current while keeping voltage constant. They simplify system wiring and reduce the need for complex junction boxes.

3. MC4 Connectors in 2025: Updated Standards and Compatibility

As of 2025, IEC 62852 and UL 6703 define the performance and safety standards for PV connectors. Modern MC4 connectors now feature:

• Improved resistance to temperature cycling and UV degradation

• Compatibility with 10 AWG–12 AWG cables

• Enhanced lock mechanisms to prevent accidental disconnection

Note: Avoid mixing connectors from different brands unless certified as compatible—doing so may cause poor contact or overheating.

4. How to Choose the Right Connector for Your Solar System

When selecting connectors, consider:

a. Voltage and Current Rating – Match your system’s electrical parameters.

b. Cable Size Compatibility – Ensure wire gauge fits connector specifications.

c. Material Quality – Look for tinned copper contacts and flame-retardant housing.

d. Certification – Always choose connectors compliant with IEC or UL standards.

e. Brand Reliability – Trusted brands offer better durability and performance.

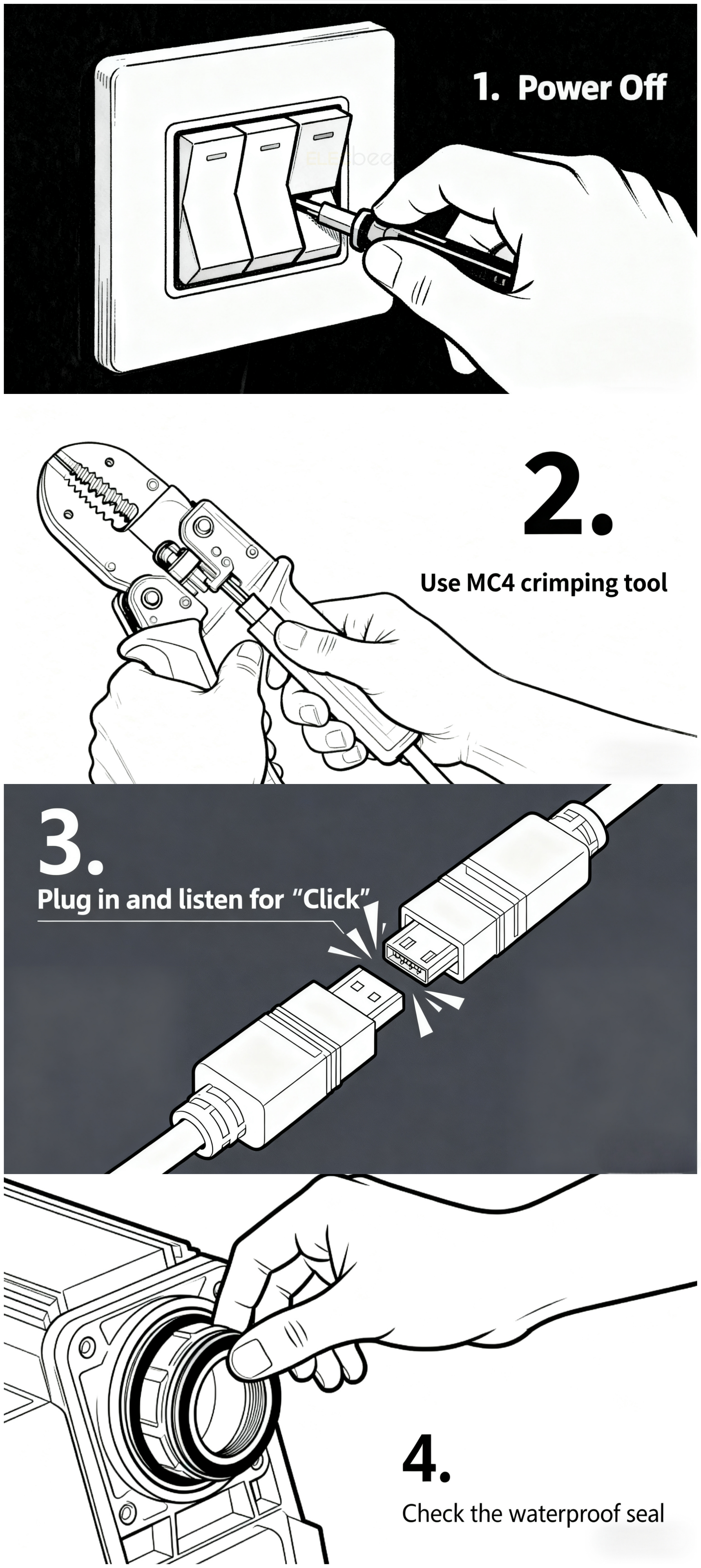

Installation and Safety Tips

• Turn off the system before connecting or disconnecting any PV connectors.

• Use certified MC4 crimping tools for proper terminal attachment.

• Inspect seals regularly to prevent water ingress.

• Avoid mixing different connector types in the same system.

5. Common Issues and Maintenance Practices

Routine maintenance ensures safety and efficiency:

• Check for cracked housings or corroded contacts.

• Clean connectors using dry air or alcohol wipes—never water.

• Replace damaged connectors immediately to prevent power loss or arcing.

6. FAQ: Photovoltaic Connectors in Modern Solar Applications

Q1: Can I mix MC4 connectors from different brands?

Not recommended. Different tolerances can cause poor sealing or electrical failure.

Q2: Are MC4 connectors waterproof?

Yes, most are IP67 rated, suitable for outdoor conditions.

Q3: How often should I inspect PV connectors?

At least once a year, or after extreme weather events.

7. Conclusion

Photovoltaic connectors may be small, but they are the unsung heroes of solar energy systems. Choosing high-quality MC4 connectors and maintaining them properly ensures long-term efficiency and safety. As solar power continues to expand globally in 2025, understanding these connectors is essential for every installer, engineer, and solar enthusiast.